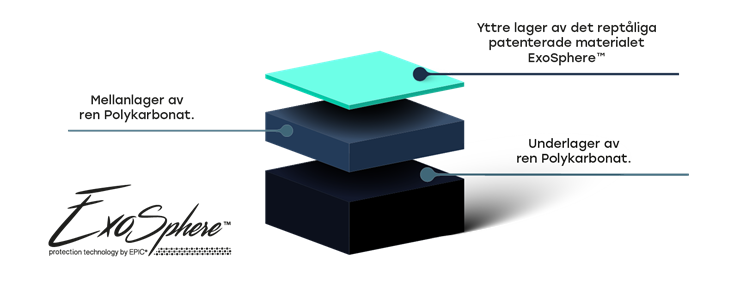

EPIC ExoSphere™

ExoSphere is a unique shell technology from EPIC. Made from 100% newly produced polycarbonate raw material which has proven to be one of the best materials for suitcases. The outer layer is a matte, silky finish that is extremely scratch and abrasion resistant while the dual-layer design reduces weight and material usage, together creating a reinforcing, reinforcing shield.

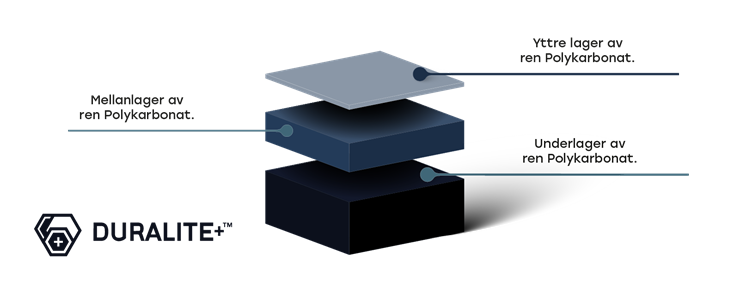

EPIC DuraLITE+™

For our DuraLITE+ material, we use at least two layers of the very best pure polycarbonate material on the market, along with an extra outer film of polycarbonate that increases its strength and impact resistance. Depending on the product, the outer surface varies, e.g. for printed bags we use a high-contrast film that makes colors and prints pop more than was possible before.

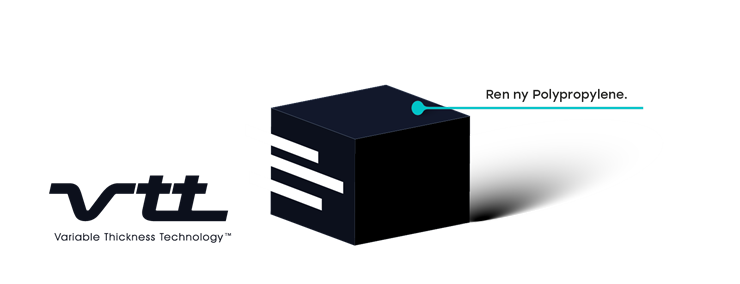

EPIC VTT™

VTT stands for Variable Thickness Technology and is our unibody polypropylene material and manufacturing process, basically meaning that we manufacture these shells with high precision in variable thickness to optimize strength while making it as light as possible. We really love polypropylene for its strength rich details that we can create with it.

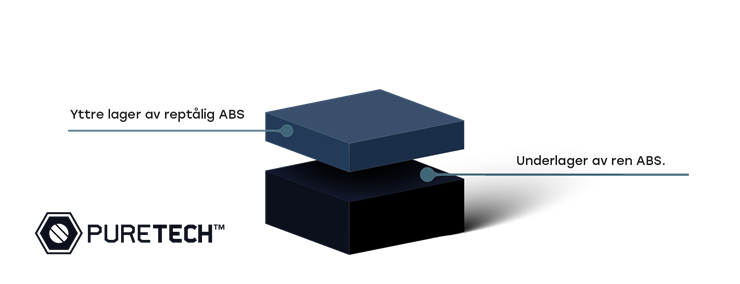

EPIC PureTECH™

The material consists of a composite of pure ABS in two layers. The special pureTECH luster in the outer film allows us to create the most beautiful colors for every season, while the unique composition in the manufacturing makes the shell tougher, stronger and more scratch resistant.

EPIC Standard™

We see the future in easily replaceable wheels with standard mounting, which made us come up with the revolutionary invention EPIC STANDARD. This patented system makes it very easy to change the wheels, either to new ones if you wear them out, or to another wheel model that suits your needs. And the best part is, as long as the suitcase model is marked with EPIC STANDARD, the wheels will fit exactly, no matter which suitcase model it is.

ZIPSEAL™

EPIC's patented zipper solution. The rubber-coated, waterproof zipper is recessed into the shell, which makes it extra protected against scratches and bumps. The solution also means less material and greater precision in the manufacturing process, simpler and more efficient.